Categories

- News (120)

- case study (6)

encapsulation

LEDs are available in discrete and integrated packages. LED discrete devices belong to traditional packaging, widely used in various related fields, after more than 40 years of development, has formed a series of mainstream product forms. Chip integration modules are currently personalized packaging, mainly designed and produced for some individual application products, and have not yet formed mainstream product forms.

The traditional LED approach is not only labor-consuming, time-consuming, but also costly, due to the lack of ready-made suitable core light source components.

In fact, we can combine the “LED light source discrete device →MCPCB light source module” into one, directly transfer and mount the semiconductor chip, integrate it on the MCPCB to make a COB light source module, and the electrical connection between the chip and the substrate is realized by the lead stitching method, and covered with resin to ensure reliability, which not only saves labor and time, but also saves the cost of device packaging.

Compared with discrete LED devices, COB light source modules can save the primary packaging cost of LED, the cost of light engine module production and secondary light distribution in the application, and the actual calculation can reduce the cost of light source by about 30%. In terms of performance, through reasonable design and microlens molding, COB light source module can effectively avoid the disadvantages of point light and glare in the combination of discrete light source devices; It can also effectively improve the color rendering of the light source without significantly reducing the efficiency and life of the light source by adding an appropriate combination of red chips. In terms of application, COB light source module can make installation and production simpler and more convenient, and effectively reduce the application cost; In terms of production, the existing process technology and equipment can fully support the large-scale manufacturing of COB light source modules with high yield rate.

Product introduction

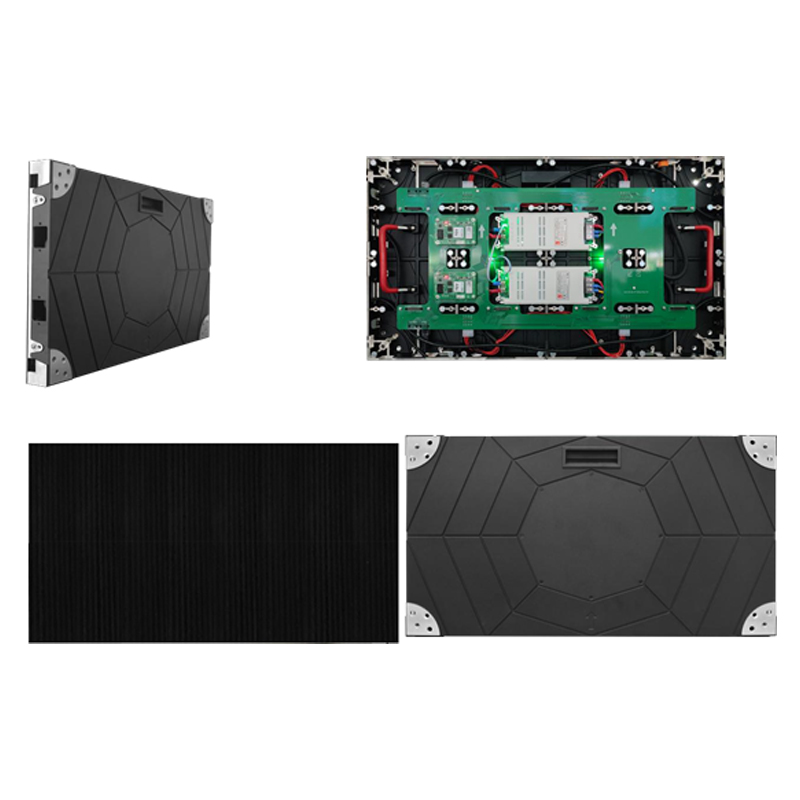

COB (chip-on-board) is the chip package on the board, it is a new product COB full-color developed by Visualpower based on the planar technology of dispensing solid crystal + SMD accurate dispensing technology, the product process is first on the surface of the substrate with thermal conductive epoxy resin (generally with epoxy resin doped with silver particles) to cover the silicon wafer placement point, and then the silicon wafer is directly placed on the surface of the substrate, heat treatment until the silicon wafer is firmly fixed on the substrate, Wire welding is then used to establish a direct electrical connection between the silicon wafer and the substrate. This process is simplified compared to dot matrix module full color and SMD full color, so it is convenient for mass production.对比

Process costs

SMD full color: The cost of raw materials for this product is more expensive, the production and processing technology is more complicated, and the input and cost are higher.

COB full color: COB eliminates the concept of bracket, no electroplating, no reflow soldering, no patch, and the process is reduced by 1/3. The efficiency of COB packaging is comparable to SMD in solidification and wire bonding processes, but the efficiency of COB packaging is much higher in dispensing, separation, spectroscopy and packaging. The labor and manufacturing costs of traditional SMD packaging account for about 15% of the material cost, while COB accounts for only 10%, and the cost is at least 5% compared with SMD full color.

Optical electrical properties

COB full color has good color consistency, large viewing angle, uniform spot, high brightness, good color mixing effect, etc., which are the characteristics and advantages that SMD full color and dot matrix full color cannot surpass.

Large viewing angle, high brightness, COB adopts heat sink process technology, which can ensure that the LED has the industry-leading heat lumen maintenance rate (95%). The following is a picture of the appearance and angle light shape comparison of dispensing and SMD

COB full-color appearance drawingSMD full-color appearance drawing

COB has better visual consistency. From the appearance alone, it can be seen that there are hundreds of luminous points on the dispensing board are on the same PCB board, that is, on the same horizontal plane, so the luminous points are on the same reference point, so that the spot is more uniform, but the SMD is pasted on the PCB board one by one, there will definitely be high and low, so that the spot is uneven, so that the visual effect is worse than the effect of encapsulated with COB.

COB has better light quality

The traditional SMD package form is to mount multiple discrete components on the PCB board to form LED applications. This practice has the problems of point light, glare and ghosting, which are obvious from the diagram; COB, on the other hand, is an integrated package and is an area light source, which not only has a large viewing angle for advantage 1, but also reduces the loss of light refraction.

The COB perspective is larger. The Visualpower COB full-color viewing angle is much larger than the SMD full-color viewing angle, the SMD full-color viewing angle is about 110 degrees, but the COB full-color viewing angle can reach 140-170 degrees while the brightness will not be weakened, and the vertical angle also has a wide viewing angle of 140-170 degrees, which are particularly advantageous in some applications.

From the above comparison, whether from the perspective size or the luminous effect map, the visual effect of COB full color is better than SMD full color.

Solid crystal placement

COB solid crystal placement: RGB wafer is placed in a straight line, the lens above the wafer is a smooth curved surface, the lens refracts the light very well, when the three-color light through the lens will be refracted so that the three-color light is mixed more evenly, the color mixing effect is good, the spot is uniform so as to give people a good visual effect, the display effect is more realistic, but SMD full color does not have this characteristic, because the top of the SMD is a plane so the refraction effect is general, so the color matching effect is worse than COB, The following is a comparison of the light distribution curves of the two, which can more clearly see the advantages of COB full color:

The consistency of the COB full-color curve is good, while the SMD full-color curve is not consistent, and the red light curve and the blue/green curve are greatly separated, so the effect is worse than that of COB full color.

reliability

Low thermal resistance

The system thermal resistance of traditional SMD packaging applications is: chip-solid glue-solder joint-solder paste-copper foil-insulating layer-aluminum, while the system thermal resistance of COB packaging is: chip-solid crystalline-aluminum, obviously the system thermal resistance of COB packaging is much lower than that of traditional SMD packaging, which greatly improves the life of LED.

In addition, the Visualpower COB dispensing chip is directly fixed on the PCB board, so the heat dissipation area is large, so that the wafer junction temperature is not easy to rise, resulting in better light decay, and the product quality is relatively stable; The SMD chip is fixed in the cup, not in direct contact with the PCB board, so that the heat dissipation area is small, which directly leads to poor heat dissipation performance, so it will cause the die junction temperature to rise, resulting in greater light decay. And these reasons are the bottleneck of the development of SMD full-color technology.

Waterproof, moisture-proof and UV-proof

COB because of the use of board dispensing into the lens packaging method, so in the outdoor application, in the waterproof moisture and UV protection performance is better, while SMD generally uses PPA material bracket, in waterproof and moisture and UV protection is poor, and waterproof and moisture prevention problems are not solved, it is easy to appear failure, dimming, rapid decay and other quality problems.